Time: 2024-02-21 17:44:48View:

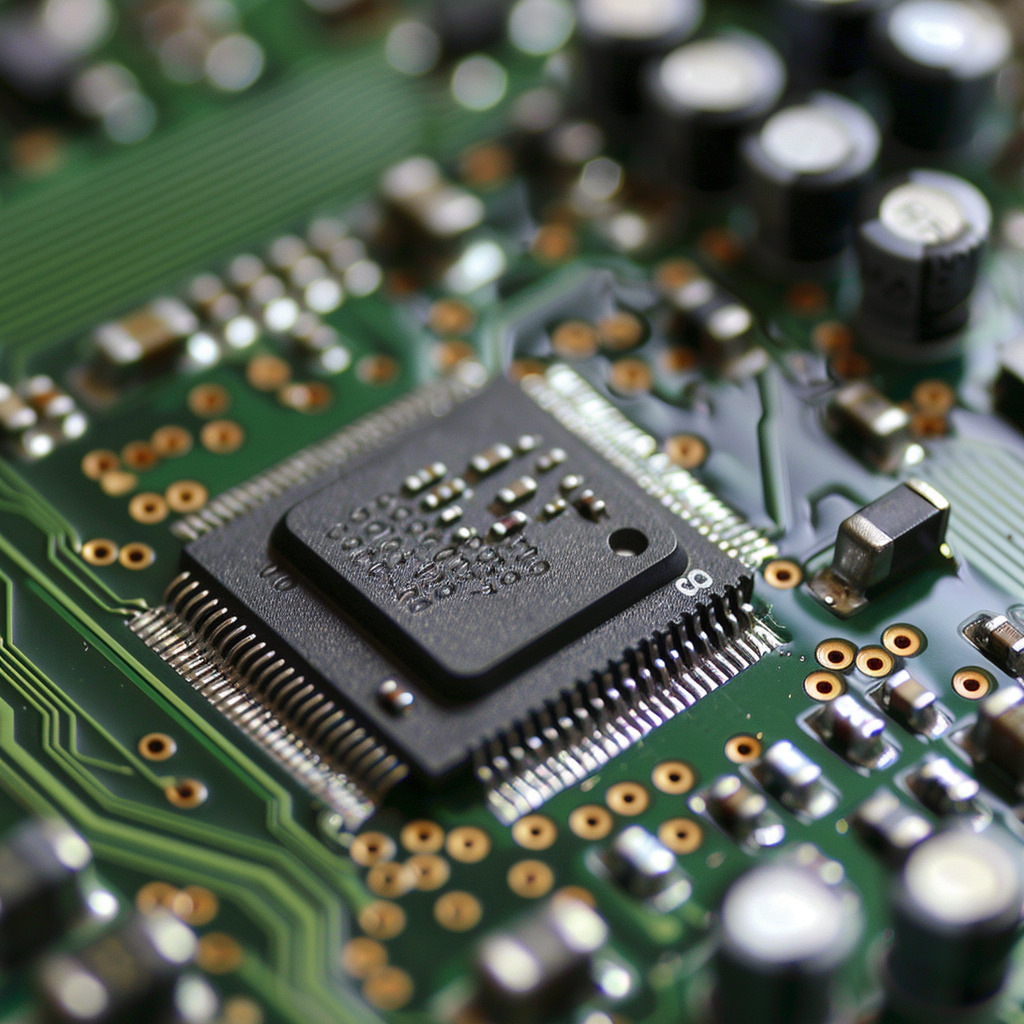

PIC microcontrollers, also known as Programmable Interface Controllers, are a family of microcontrollers developed by Microchip Technology Inc. PIC microcontrollers are widely used in various embedded systems and electronics applications due to their versatility, ease of use, and cost-effectiveness. They are particularly popular in industrial automation, consumer electronics, automotive systems, and other fields that require microcontroller-based control and processing capabilities.

PIC microcontrollers are based on a reduced instruction set computer (RISC) architecture, which emphasizes simplicity and efficiency. They typically feature a small footprint with integrated memory, input/output (I/O) ports, and a central processing unit (CPU) core. The CPUs in PIC microcontrollers execute instructions in a single clock cycle, allowing for high-speed operation and real-time control.

One of the key advantages of PIC microcontrollers is their extensive range of available models, offering a wide selection of features and capabilities. They come in various configurations, including different memory sizes, clock speeds, and peripheral options to suit different application requirements. This flexibility allows developers to choose the most suitable microcontroller for their specific project, balancing factors such as cost, performance, and power consumption.

PIC microcontrollers provide a rich set of integrated peripherals, including analog-to-digital converters (ADCs), digital-to-analog converters (DACs), timers, serial communication interfaces (e.g., UART, SPI, I2C), and general-purpose I/O pins. These peripherals enable interfacing with external devices, sensors, and other components, making PIC microcontrollers well-suited for a wide range of applications.

Programming PIC microcontrollers is typically done using specialized integrated development environments (IDEs) provided by Microchip, such as MPLAB X IDE. These IDEs offer a comprehensive set of tools, including compilers, debuggers, and simulators, to facilitate software development and debugging. The programming languages commonly used for PIC microcontrollers include assembly language and high-level languages like C or C++.

PIC microcontrollers are known for their reliability, low power consumption, and robustness, making them suitable for both battery-powered and industrial applications. They are often used in systems that require real-time control, such as motor control, automation, data acquisition, and embedded systems.

Microchip provides extensive documentation, application notes, and a vast library of code examples and reference designs for PIC microcontrollers, enabling developers to quickly get started and accelerate their project development. Additionally, the availability of a large community of PIC microcontroller enthusiasts and experts further facilitates knowledge sharing, troubleshooting, and support.

In summary, PIC microcontrollers are versatile and cost-effective microcontrollers widely used in embedded systems and electronics applications. They offer a range of models with different features, integrated peripherals, and programming options. With their small footprint, real-time control capabilities, and extensive support ecosystem, PIC microcontrollers are a popular choice for a broad range of applications, from consumer electronics to industrial automation.

PIC microcontrollers are based on a reduced instruction set computer (RISC) architecture, which emphasizes simplicity and efficiency. They typically feature a small footprint with integrated memory, input/output (I/O) ports, and a central processing unit (CPU) core. The CPUs in PIC microcontrollers execute instructions in a single clock cycle, allowing for high-speed operation and real-time control.

Below is a related video about PIC microcontrollers architecture:

PIC microcontrollers and Arduino are two popular platforms used for developing embedded systems and electronics projects. While they share similarities in terms of their application in the field of microcontroller-based control and processing, there are some key differences between the two.

PIC microcontrollers, as discussed earlier, are a family of microcontrollers developed by Microchip Technology Inc. They are known for their versatility, extensive range of models, and integrated peripherals. PIC microcontrollers offer a wide selection of features and capabilities, making them suitable for a broad range of applications. They are typically programmed using specialized IDEs, such as MPLAB X IDE, and are often programmed in assembly language or high-level languages like C or C++.

Arduino, on the other hand, is an open-source electronics platform that consists of hardware boards and a software development environment. Arduino boards are built around microcontrollers from various manufacturers, including Atmel (now Microchip), and have gained significant popularity due to their ease of use and beginner-friendly nature. Arduino boards are equipped with a microcontroller, such as the Atmel AVR series, and come with pre-programmed bootloaders that simplify the programming process.

One of the main differences between PIC microcontrollers and Arduino is the level of complexity and flexibility. PIC microcontrollers provide a greater level of flexibility and customization due to the wide range of models and integrated peripherals they offer. This allows developers to choose the most suitable microcontroller for their specific project requirements. Arduino boards, on the other hand, are designed to provide a simplified and user-friendly experience, making them more accessible for beginners and those without extensive electronics knowledge.

Programming on Arduino boards is done using the Arduino Software (IDE), which provides a simplified programming environment based on the Wiring programming language. The Arduino IDE abstracts many low-level details, making it easier for beginners to start programming without delving into the intricacies of microcontroller-specific features. This ease of use, extensive online community support, and vast library of pre-built software components, known as "sketches," have contributed to Arduino's popularity among hobbyists, artists, and educators.

In terms of application domains, PIC microcontrollers have a broader reach due to their extensive range of models and capabilities. They are commonly used in industrial automation, consumer electronics, automotive systems, and other professional applications that require robust and flexible microcontroller-based control. Arduino, on the other hand, is often favored in prototyping, hobbyist projects, and educational environments, where the emphasis is on simplicity, quick development, and community support.

Another difference lies in the availability of documentation and resources. Microchip, the manufacturer of PIC microcontrollers, provides comprehensive documentation, application notes, and a vast library of code examples. Arduino, being an open-source platform with a large community, has an extensive collection of tutorials, forums, and user-contributed projects available online, making it easier for beginners to learn and find support.

In summary, while both PIC microcontrollers and Arduino are used for developing embedded systems and electronics projects, they differ in terms of complexity, flexibility, programming environments, and target audiences. PIC microcontrollers offer a wider range of models and integrated peripherals, making them suitable for diverse applications, while Arduino provides a beginner-friendly platform with simplified programming and extensive community support, which makes it popular among hobbyists and beginners.

Advantages of PIC Microcontrollers:

1. Versatility: PIC microcontrollers offer a wide range of models with different features and capabilities, allowing developers to choose the most suitable microcontroller for their specific application requirements.

2. Integrated Peripherals: PIC microcontrollers come with a rich set of integrated peripherals, such as ADCs, DACs, timers, and communication interfaces, which simplify the design process and enable interfacing with external devices and sensors.

3. Extensive Documentation and Support: Microchip provides comprehensive documentation, application notes, and a vast library of code examples, making it easier for developers to learn, troubleshoot, and accelerate their project development. The availability of a large community of PIC microcontroller enthusiasts and experts further facilitates knowledge sharing and support.

4. Real-Time Control: PIC microcontrollers are well-suited for applications that require real-time control and responsiveness, thanks to their small footprint, RISC architecture, and single-cycle instruction execution.

5. Reliability and Robustness: PIC microcontrollers are known for their reliability and robustness, making them suitable for both battery-powered and industrial applications. They are designed to operate in harsh environments and offer low power consumption options.

Disadvantages of PIC Microcontrollers:

1. Steeper Learning Curve: Compared to beginner-friendly platforms like Arduino, PIC microcontrollers may have a steeper learning curve, especially for individuals without prior experience in embedded systems or programming.

2. Limited Community Support: While the PIC microcontroller community is sizable and provides valuable resources, it may not be as vast and active as the Arduino community. This can make finding specific project examples or troubleshooting assistance slightly more challenging.

3. Lower-Level Programming: PIC microcontrollers often require low-level programming, such as assembly language or C/C++, which may be more complex and time-consuming compared to the simplified programming environments provided by platforms like Arduino.

4. Cost Considerations: Depending on the specific model and features required, PIC microcontrollers may be more expensive compared to some entry-level Arduino boards. This can be a factor to consider, especially for cost-sensitive projects or hobbyists on a budget.

5. Lack of Standardized Hardware: Unlike Arduino, which has a standardized hardware platform, PIC microcontrollers come in various configurations and pinouts. This can require additional effort and attention to hardware compatibility when designing circuits or switching between different PIC microcontroller models.

It's important to note that these advantages and disadvantages are general observations and may vary depending on the specific requirements, project complexity, and the developer's experience and familiarity with the platform.

PIC microcontrollers find widespread applications across various industries and fields. Here are some of the key areas where PIC microcontrollers are commonly utilized:

Industrial Automation: PIC microcontrollers are extensively employed in industrial automation systems for tasks such as process control, monitoring, and data acquisition. They enable precise control of machinery and equipment, interfacing with sensors and actuators, and communication with supervisory control systems.

Consumer Electronics: PIC microcontrollers are widely used in consumer electronics devices such as home appliances, smart devices, remote controls, and audio/video equipment. They provide control, interface, and processing capabilities to enhance functionality and user experience.

Automotive Systems: PIC microcontrollers are utilized in automotive applications, including engine control units (ECUs), dashboard displays, airbag systems, anti-lock braking systems (ABS), and various sensors for monitoring and control. They assist in managing complex functions and ensuring the safety and efficiency of automotive systems.

Medical Devices: PIC microcontrollers play a vital role in medical devices and healthcare systems. They are used in patient monitoring systems, infusion pumps, blood glucose meters, diagnostic equipment, and prosthetic devices. PIC microcontrollers enable accurate measurements, data processing, and communication in medical applications.

Internet of Things (IoT): PIC microcontrollers are employed in IoT devices and systems. They enable connectivity, sensor integration, and data processing for various IoT applications, including smart homes, wearable devices, environmental monitoring, and industrial IoT solutions.

Robotics: PIC microcontrollers are utilized in robotics for controlling robot movement, sensory feedback, and interaction with the environment. They enable precise motor control, sensor integration, and decision-making capabilities in robotic systems.

Embedded Systems: PIC microcontrollers are widely used in embedded systems across diverse industries. They are utilized in applications such as security systems, access control, energy management, automation, and control systems in industries like manufacturing, agriculture, and telecommunications.

The versatility, flexibility, and extensive range of models and integrated peripherals make PIC microcontrollers suitable for a wide array of electronic systems and projects.