Time: 2023-12-25 17:27:14View:

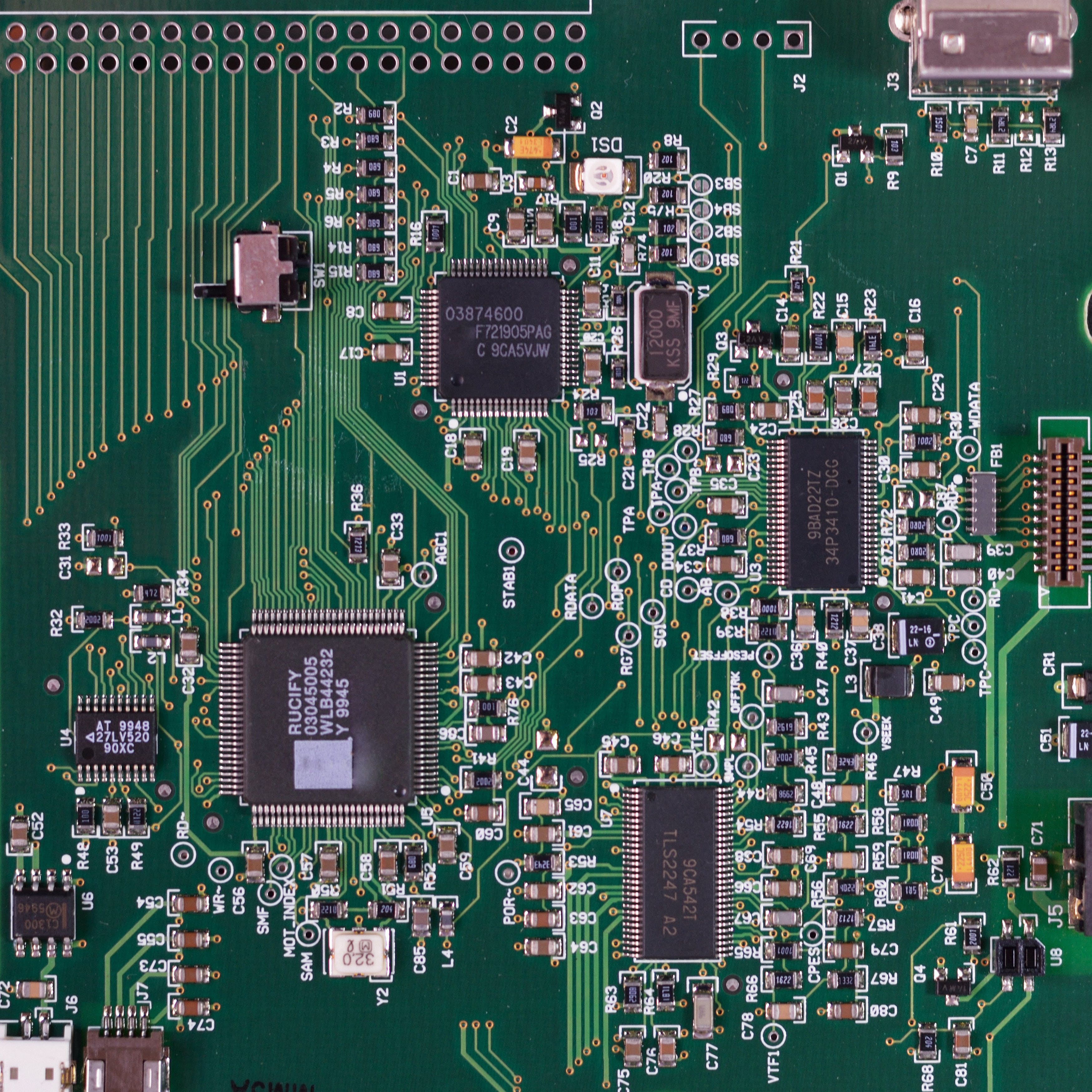

System-in-Package (SiP) is a technology that involves integrating multiple integrated circuits (ICs) or semiconductor dies into a single package in the vemeko website. This approach allows for the combination of different functional blocks, such as processors, memory, sensors, and other components, into a compact and highly integrated module. SiP offers several advantages over traditional multi-chip solutions, including reduced size, improved performance, and enhanced functionality.

In a SiP, the individual ICs or dies are typically interconnected using advanced packaging techniques, such as wire bonding, flip-chip bonding, or through-silicon vias (TSVs). These interconnections enable the different components to communicate with each other and work together as a unified system. By bringing together diverse functionalities in a single package, SiP can help to minimize the footprint of electronic devices, improve signal integrity, and reduce power consumption.

SiP technology is widely used in various applications, including mobile devices, wearables, Internet of Things (IoT) devices, and automotive electronics. It allows manufacturers to create highly integrated and feature-rich products while meeting the demands for miniaturization and performance. Additionally, SiP can facilitate rapid prototyping and product development by simplifying the integration of complex electronic systems.

Overall, System-in-Package represents a significant advancement in semiconductor packaging technology, enabling the creation of compact, efficient, and multifunctional electronic modules for a wide range of applications.

SIP (System-in-Package) and SWP (Sim Card Web Server over HTTP Protocol) are two distinct technologies that serve different purposes in the realm of electronics and telecommunications.

SIP, or System-in-Package, is a technology that involves integrating multiple integrated circuits (ICs) or semiconductor dies into a single package. This approach allows for the combination of different functional blocks, such as processors, memory, sensors, and other components, into a compact and highly integrated module. SIP offers several advantages over traditional multi-chip solutions, including reduced size, improved performance, and enhanced functionality. It is widely used in various applications, including mobile devices, wearables, Internet of Things (IoT) devices, and automotive electronics. SIP technology enables the creation of compact, efficient, and multifunctional electronic modules for a wide range of applications.

On the other hand, SWP, or Sim Card Web Server over HTTP Protocol, is a technology that enables the use of SIM cards as secure elements for mobile transactions and secure services. It allows the SIM card to act as a secure microcontroller, capable of running small applications and securely storing sensitive information such as cryptographic keys and personal identification data. SWP facilitates secure mobile payments, authentication, and other services that require strong security measures. It is an important technology in the field of mobile telecommunications and digital security, enabling the widespread adoption of mobile payment systems and secure mobile services.

In summary, while SIP focuses on the integration of multiple semiconductor components into a single package to create compact and multifunctional electronic modules, SWP is concerned with leveraging SIM cards as secure elements for mobile transactions and secure services. Both technologies play crucial roles in advancing the capabilities of electronic devices and mobile telecommunications, albeit in different domains.

System-in-Package (SiP) is a technology that involves integrating multiple integrated circuits (ICs) or semiconductor dies into a single package. SiP works by bringing together different functional blocks, such as processors, memory, sensors, and other components, into a compact and highly integrated module. This approach offers several advantages over traditional multi-chip solutions, including reduced size, improved performance, and enhanced functionality.

The process of creating a SiP involves several key steps. First, the individual ICs or semiconductor dies that make up the functional blocks are selected based on the specific requirements of the application. These components may include microprocessors, memory chips, radio frequency (RF) modules, and various sensors. Once the components are chosen, they are assembled and interconnected within a single package using advanced packaging techniques such as wire bonding, flip-chip bonding, or through-silicon vias (TSVs).

Interconnecting the components is a critical aspect of SiP technology. The interconnections enable the different functional blocks to communicate with each other and work together as a unified system. Careful consideration is given to the layout and design of the interconnections to ensure optimal signal integrity, power distribution, and thermal management within the SiP.

SiP technology is widely used in various applications, including mobile devices, wearables, Internet of Things (IoT) devices, and automotive electronics. By integrating multiple components into a single package, SiP enables the creation of compact, efficient, and multifunctional electronic modules for a wide range of applications. This approach is particularly valuable in scenarios where space constraints, power efficiency, and performance are critical factors.

In summary, SiP works by integrating multiple ICs or semiconductor dies into a single package, enabling the creation of highly integrated electronic modules. The technology involves careful component selection, assembly, and interconnection to achieve compactness, improved performance, and enhanced functionality in electronic devices. SiP represents a significant advancement in semiconductor packaging technology, offering a versatile solution for creating complex electronic systems in a compact form factor.

The key difference between SoC (System-on-Chip) and SiP (System-in-Package) lies in how the various components are integrated into a single unit, and the level of integration they achieve.

SoC, or System-on-Chip, refers to an integrated circuit that incorporates most or all components of a computer or electronic system onto a single chip. This includes the central processing unit (CPU), memory, input/output interfaces, and other essential components. The integration of these elements onto a single chip results in a highly compact and efficient solution. SoC is commonly used in a wide range of electronic devices, including smartphones, tablets, and IoT devices, where space, power efficiency, and performance are critical considerations.

On the other hand, SiP, or System-in-Package, involves integrating multiple integrated circuits (ICs) or semiconductor dies into a single package, but not necessarily onto a single chip. SiP allows for the combination of different functional blocks, such as processors, memory, sensors, and other components, into a compact and highly integrated module. This approach offers advantages over traditional multi-chip solutions, including reduced size, improved performance, and enhanced functionality. SiP is widely used in various applications, including mobile devices, wearables, IoT devices, and automotive electronics.

The distinction between SoC and SiP lies in the level of integration. SoC achieves a high level of integration by incorporating all essential components onto a single chip, while SiP integrates multiple components into a single package, which may consist of multiple chips or dies. SoC is often used when a high degree of integration and performance is required, while SiP is favored when a combination of diverse functionalities and components needs to be integrated into a compact module.

In summary, SoC and SiP represent different approaches to achieving integration in electronic systems. SoC focuses on integrating all components onto a single chip, while SiP involves integrating multiple components into a single package, offering flexibility and enhanced functionality in a compact form factor. Both technologies play crucial roles in advancing the capabilities of electronic devices, each catering to specific design and performance requirements.

System-in-Package (SiP) technology finds applications across a wide range of industries and electronic devices due to its ability to integrate multiple functional blocks into a compact and highly integrated module. The versatility and flexibility of SiP make it suitable for various applications where space constraints, performance, and functionality are critical considerations.

In the realm of consumer electronics, SiP is commonly used in mobile devices such as smartphones and tablets. These devices require compact, multifunctional modules that integrate processors, memory, sensors, and wireless communication components. SiP enables the creation of highly integrated electronic modules that contribute to the miniaturization and enhanced performance of these devices.

The Internet of Things (IoT) is another area where SiP technology is extensively utilized. IoT devices often require a combination of sensors, microcontrollers, wireless communication modules, and power management components in a compact form factor. SiP allows for the integration of these diverse functionalities into a single package, enabling the development of efficient and feature-rich IoT devices for various applications, including smart home automation, industrial monitoring, and environmental sensing.

In the automotive industry, SiP technology is employed in advanced driver-assistance systems (ADAS), infotainment systems, and vehicle connectivity modules. These applications demand compact and reliable electronic modules that can integrate processing units, sensors, communication interfaces, and control modules. SiP facilitates the creation of integrated modules that contribute to the performance, safety, and connectivity features of modern vehicles.

Furthermore, SiP is utilized in medical devices, wearables, industrial automation, and communication equipment, where the integration of diverse functionalities into a compact form factor is essential. Its applications extend to areas such as aerospace, defense, and scientific instrumentation, where space, weight, and power constraints are critical factors.

In summary, SiP technology finds applications in a diverse array of industries and electronic devices, including consumer electronics, IoT, automotive systems, medical devices, wearables, industrial automation, and communication equipment. Its ability to integrate multiple functional blocks into a compact and highly integrated module makes it a versatile and valuable solution for addressing the miniaturization, performance, and functionality requirements of modern electronic systems.