Field-Programmable Gate Arrays (FPGAs) are becoming increasingly important in the field of robotics due to their flexibility, parallel processing capabilities, and real-time data handling. Unlike traditional processors (CPUs and GPUs), FPGAs can be reconfigured to optimize performance for specific tasks, making them well-suited for robotic systems that require precise control, rapid processing, and adaptability.

1. Real-Time Processing

FPGAs excel at real-time data processing, which is critical in robotics for tasks such as:

- Sensor Fusion: Combining data from multiple sensors (e.g., LiDAR, cameras, IMUs) to create an accurate environmental model.

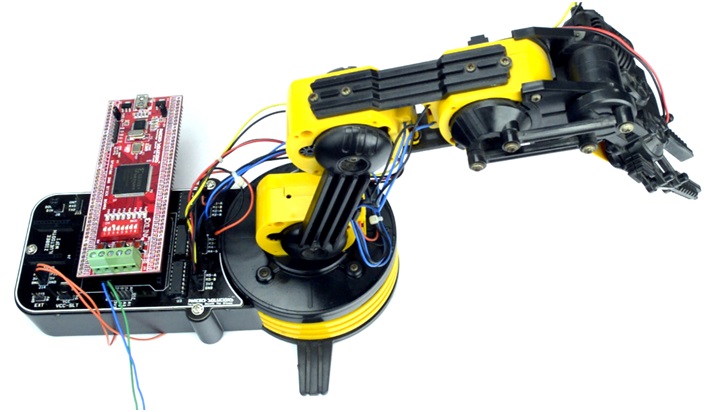

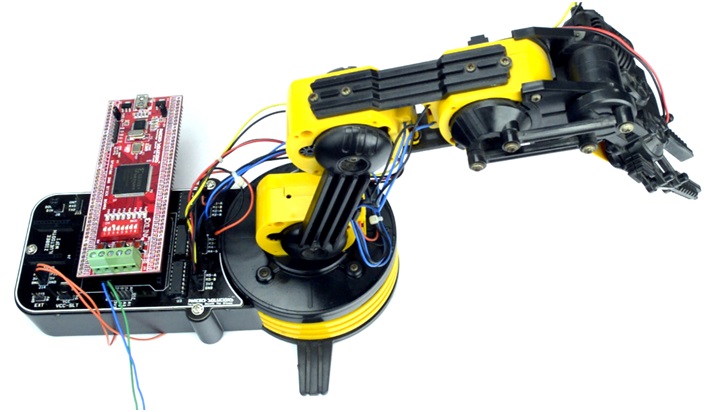

- Real-Time Control: Implementing precise motor control algorithms for tasks like balancing robots or controlling robotic arms.

- Obstacle Detection and Avoidance: Processing data from vision systems or LiDAR in real-time to avoid collisions.

Example Use Case: Autonomous drones use FPGAs to process sensor data in real time for stabilization and path planning.

2. Parallel Processing Capabilities

FPGAs can handle multiple tasks simultaneously, unlike CPUs, which process instructions sequentially. In robotics:

- Computer Vision: Real-time object detection and image recognition using hardware-accelerated neural network models.

- Path Planning Algorithms: Efficient computation of pathfinding algorithms (e.g., A* or Dijkstra).

- Machine Learning Inference: Accelerating AI models for tasks like speech recognition, gesture analysis, and predictive maintenance.

Example Use Case: FPGAs can implement deep learning models to identify and track objects in robotic vision systems.

3. Energy Efficiency

FPGAs are generally more energy-efficient compared to GPUs for the same computational workload, which is vital for mobile robots or drones operating on limited power supplies.

- Power Management: Optimized designs reduce energy consumption during idle states.

- Low-Latency Communication: Reduced latency between processing units and actuators improves energy efficiency.

Example Use Case: Autonomous delivery robots rely on FPGAs for efficient battery usage while processing navigation data.

4. Customizability and Flexibility

FPGAs are reconfigurable, allowing developers to update or optimize algorithms without replacing hardware.

- Prototyping: Testing new algorithms on FPGA hardware before finalizing designs.

- Hardware Acceleration: Certain computational tasks can be offloaded to dedicated FPGA cores.

Example Use Case: Research robots use FPGAs for prototyping different motor control algorithms without hardware modifications.

5. Integration with AI and Neural Networks

Modern FPGAs support frameworks like TensorFlow and PyTorch, allowing them to execute AI inference workloads efficiently.

- Edge AI Computing: Enabling robots to make intelligent decisions without relying on cloud computing.

- Adaptive Learning: Real-time adjustments to robotic behavior based on AI feedback.

Example Use Case: Service robots use FPGA-based AI inference engines to process natural language commands.

6. Challenges in Using FPGAs for Robotics

- Programming Complexity: FPGA development requires expertise in hardware description languages (e.g., VHDL, Verilog).

- Higher Initial Cost: FPGAs can be expensive compared to microcontrollers.

- Scalability Issues: Scaling FPGA designs for larger systems can be challenging.

7. Future Trends in FPGA Robotics Integration

- Enhanced AI Support: More FPGA vendors are integrating AI cores into their chips.

- Hybrid Architectures: Combination of CPUs, GPUs, and FPGAs for maximum efficiency.

- Edge Computing Focus: Robotics systems increasingly rely on FPGA-powered edge AI for local data processing.

Conclusion

FPGAs are a powerful technology for robotics, offering unmatched parallel processing, real-time responsiveness, and customization. As AI and robotics continue to converge, FPGAs will play an even larger role in enabling advanced robotic systems across industries, from autonomous vehicles to industrial automation.