Time: 2025-04-29 14:42:23View:

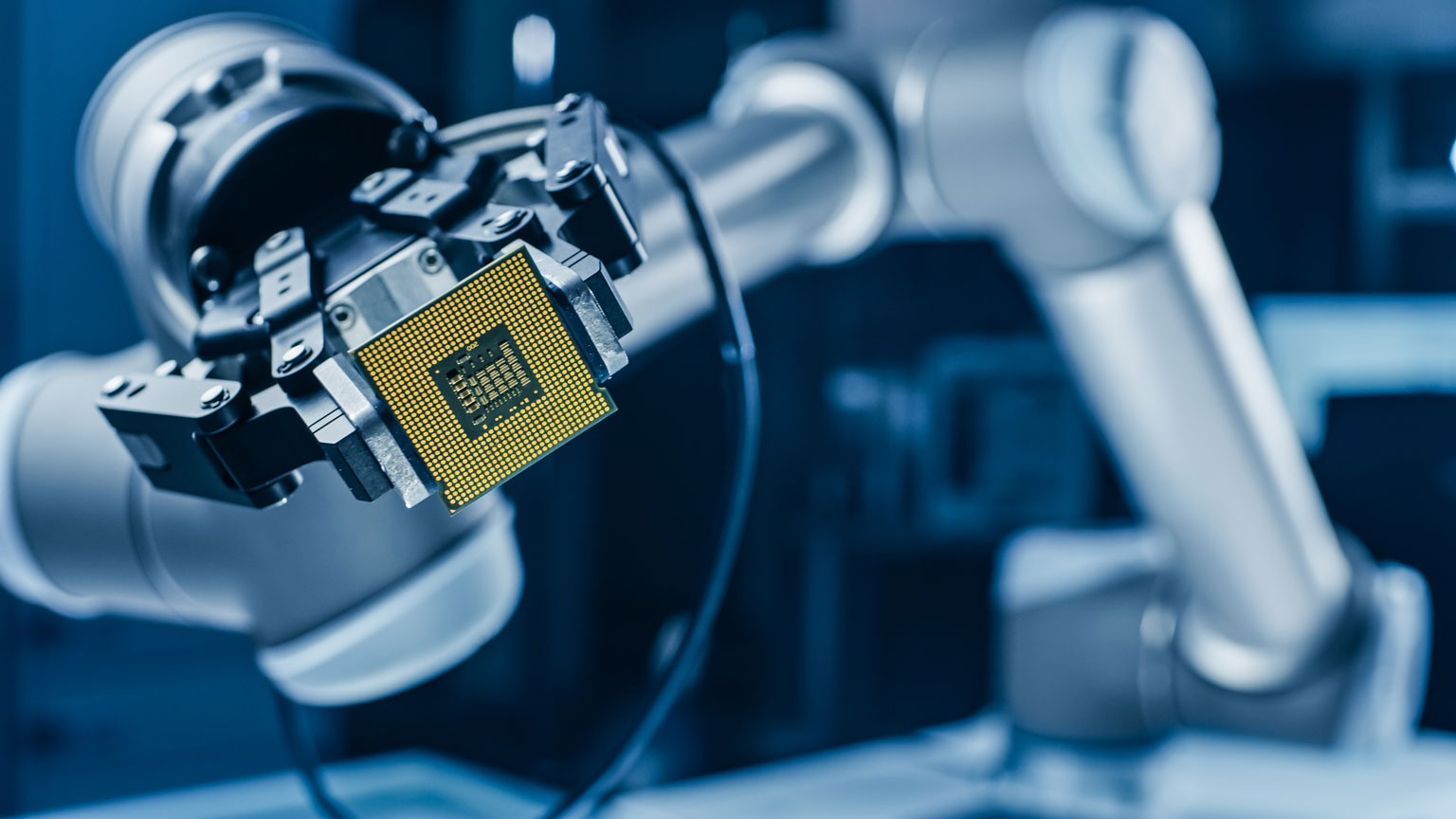

In industrial robotics, FPGAs play a pivotal role in real-time control, sensor fusion, and high-speed communication. Xilinx (now AMD) and Intel (Altera) dominate this space with distinct architectures tailored for robotic applications. Here’s a detailed comparison:

UltraScale+ / Versal ACAP

Hardened AI/ML cores for robotic vision (e.g., object detection).

High-speed serial transceivers (up to 112 Gbps) for EtherCAT/TSN.

DSP Slices: Optimized for motor control (PWM, PID loops).

Adaptive Compute Acceleration Platform (ACAP): Combines FPGA fabric with AI Engines (AIEs) and scalar/vector processors.

Key Features:

Stratix 10 / Agilex

HyperFlex registers: Reduce latency in real-time control loops.

Tensor Blocks: Accelerate robotic path-planning algorithms.

PCIe Gen4: For high-bandwidth sensor data (LiDAR, 3D vision).

Hybrid Architecture: FPGA + integrated ARM Cortex-A53 (Hard Processor System, HPS).

Key Features:

| Application | Xilinx Strengths | Intel Strengths |

|---|---|---|

| Motor Control | More DSP slices (up to 5,000 in Versal) | Lower-latency HyperFlex pipelines |

| Sensor Fusion | AI Engines for LiDAR/radar data fusion | ARM HPS for Linux-based preprocessing |

| Real-Time Ethernet | TSN/IP cores with <1 µs jitter | Hardened EtherCAT MAC in Agilex |

| Computer Vision | Versal AI Edge (TOPS/Watt optimized) | OpenVINO toolkit for Intel FPGAs |

Vitis Unified Platform:

Supports C/C++/Python via Vitis HLS for rapid algorithm deployment.

ROS 2 Integration: Libraries for robotic middleware (e.g., Vitis AI for perception).

PetaLinux: Custom Linux distro for Versal’s ARM cores.

Quartus Prime + Intel OneAPI:

DSP Builder: Simplifies motor control algorithm design.

ROS Compatibility: Through OpenVINO and HPS-based Linux.

FPGA SDK for OpenCL: For GPU-like acceleration of parallel tasks.

| Metric | Xilinx Versal AI Edge | Intel Agilex 7 |

|---|---|---|

| Power (Typical) | 20W (for vision pipeline) | 25W (with HPS active) |

| Cooling | Passive cooling feasible | Often requires active cooling |

| Use Case Fit | Edge robots (mobile, battery) | Stationary arms/CNC machines |

Both support TSN (Time-Sensitive Networking), but with different implementations:

Xilinx: Dedicated TSN Subsystem IP with IEEE 802.1AS sync.

Intel: Hardened TSN MAC in Agilex, lower CPU overhead.

Example: For a robotic assembly line using EtherCAT, Xilinx offers softer IP flexibility, while Intel provides hardened blocks for deterministic latency.

Xilinx:

Functional Safety (FuSa): Versal certified to ISO 13849 (PLd/SIL3).

SEU Mitigation: UltraRAM + CRC for radiation-hardened apps.

Intel:

Lockstep ARM Cores: In Stratix 10 for fault tolerance.

ECC on All Memories: Critical for automotive/robotics.

Xilinx: Higher cost (Versal premium), but broader IP ecosystem.

Intel: Competitive pricing for mid-range (Cyclone 10GX), but Agilex is pricey.

Tip: For cost-sensitive designs, Xilinx Artix-7 or Intel Cyclone V are common in cobots.

Xilinx: Used in KUKA’s robot controllers for adaptive motion planning.

Intel: Powers ABB’s YuMi cobot vision system via OpenVINO.

| Choose Xilinx If... | Choose Intel If... |

|---|---|

| Need AI/ML acceleration (Versal AI) | Prefer ARM HPS for Linux integration |

| Require highest-speed transceivers | Focus on low-latency control (HyperFlex) |

| Developing ROS 2-based systems | Using OpenVINO for vision tasks |

Xilinx: Pushing adaptive SoCs (FPGA+AIE+CPU) for autonomous robots.

Intel: Betting on chiplet-based Agilex for modular robotics.

Bottom Line:

Xilinx excels in heterogeneous compute (vision/AI).

Intel leads in deterministic real-time control.