Time: 2025-05-09 11:25:01View:

Creating a product using an FPGA (Field-Programmable Gate Array) involves hardware design, firmware development, and system integration. Below is a structured guide to help you build an FPGA-based product from concept to production.

Before selecting an FPGA, clarify:

✅ Functionality (Digital signal processing? AI acceleration? High-speed I/O?)

✅ Performance Needs (Clock speed, latency, power consumption)

✅ I/O Interfaces (USB, Ethernet, HDMI, GPIO, ADC/DAC)

✅ Power Constraints (Battery-powered or mains-powered?)

✅ Cost & Scalability (Low-cost FPGA vs. high-end for prototyping)

Popular FPGA vendors:

Microchip (Microsemi) (PolarFire, SmartFusion2)

Selection Criteria:

✔ Logic Cells (LUTs, Flip-Flops for complexity)

✔ DSP Slices (For math-heavy tasks)

✔ Memory (Block RAM, External DDR)

✔ Hard IP Cores (PCIe, Ethernet, USB)

✔ Power Efficiency (Critical for portable devices)

Schematic Design (Use KiCad, Altium, OrCAD)

Add FPGA, power supply (1.0V, 1.2V, 3.3V rails), clock sources (crystals/oscillators).

Include necessary peripherals (SDRAM, Flash, Ethernet PHY, etc.).

Add JTAG/SWD for programming & debugging.

PCB Layout

Follow FPGA manufacturer’s PCB Design Guidelines (critical for signal integrity).

Use controlled impedance routing for high-speed signals (DDR, PCIe, LVDS).

Optimize power distribution network (PDN) with decoupling capacitors.

Write Register-Transfer Level (RTL) code for custom logic.

Example (Verilog):

module led_blinker ( input clk, output reg led); reg [31:0] counter; always @(posedge clk) begin counter <= counter + 1; if (counter == 25_000_000) begin led <= ~led; counter <= 0; end endendmodule

Use Xilinx Vitis HLS or Intel HLS to convert C/C++ to HDL.

Use Xilinx Zynq (ARM + FPGA) or Intel Cyclone V (HPS + FPGA).

Run Linux on ARM & offload tasks to FPGA.

Simulate using ModelSim, Questa, or Verilator.

Test on Development Boards (e.g., Xilinx PYNQ, DE10-Nano) before custom PCB.

Use SignalTap (Intel) / ChipScope (Xilinx) for real-time debugging.

Manufacture PCB (JLCPCB, PCBWay).

Solder & Assemble (Use hot air/reflow for BGA FPGAs).

Power-On Test (Check voltages, clock signals).

Program FPGA (Via JTAG or Flash memory).

Validate I/O (Test GPIO, UART, Ethernet, etc.).

Optimize FPGA Bitstream for size & speed.

Secure Firmware (Encrypt bitstream to prevent cloning).

Consider ASIC Conversion (If mass-producing, move from FPGA to custom chip).

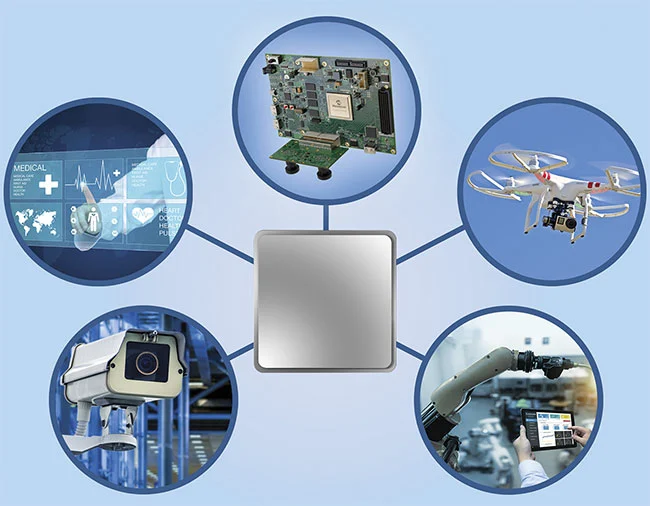

High-Speed Trading Systems (Ultra-low latency)

Medical Imaging Devices (Real-time processing)

Robotics & Motor Control (Custom PWM & sensor fusion)

Cryptocurrency Miners (High parallel computation)

FPGA Dev Boards:

Xilinx: Basys 3, PYNQ-Z2

Intel: DE10-Nano, Cyclone V GT

Lattice: iCE40-HX1K

Free FPGA Tools:

Xilinx Vivado (Free WebPack)

Intel Quartus Lite

Lattice Radiant